CONTACT US

Technical advice:

Wang Gong13587361122

After-sales service:400-863-8228

Address:

Shengzhou City, Zhejiang Province

No. 25-1, Julong Road, Sanwang Industrial Zone

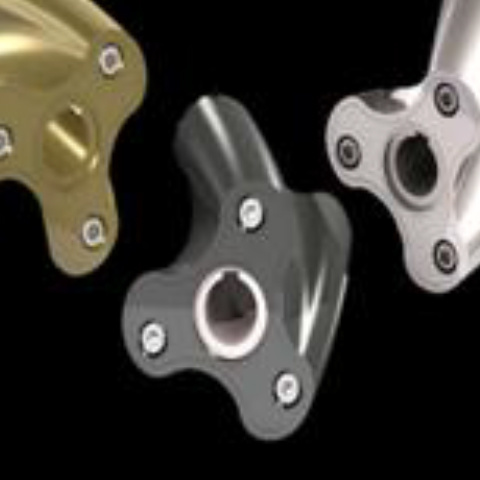

Rotary lobe pump

Nord NDB rotor pump [commonly referred to as cam rotor pump, piston rotor pump, rotary piston pump, spiral rotor pump, rotary lobe pump, rotor piston pump, piston rotor pump, rotor pump, etc.] is an original Scientific research results have achieved a major breakthrough in pump technology.

Rotor pump is a rotating positive displacement pump, through the relative movement between the rotating rotor and the pump body to change the working volume, thereby increasing the energy of the liquid. By the contact side of the rotor in the pump body and the liquid, the energy is directly applied to the liquid in the form of static pressure, and the liquid is discharged by means of the squeezing effect of the rotating rotor. At the same time, the liquid flows out of the space on the other side to form a low pressure, so that the liquid can be continuously sucked in. Suitable for a variety of media, highly versatile. Nord company after more than ten years of continuous progress, has been widely recognized by the market.

- Commodity name: Rotary lobe pump

Product characteristics

Nord NDB rotor pump [commonly referred to as cam rotor pump, piston rotor pump, rotary piston pump, spiral rotor pump, rotary lobe pump, rotor piston pump, piston rotor pump, rotor pump, etc.] is an original Scientific research results have achieved a major breakthrough in pump technology.

Rotor pump is a rotating positive displacement pump, through the relative movement between the rotating rotor and the pump body to change the working volume, thereby increasing the energy of the liquid. By the contact side of the rotor in the pump body and the liquid, the energy is directly applied to the liquid in the form of static pressure, and the liquid is discharged by means of the squeezing effect of the rotating rotor. At the same time, the liquid flows out of the space on the other side to form a low pressure, so that the liquid can be continuously sucked in. Suitable for a variety of media, highly versatile. Nord company after more than ten years of continuous progress, has been widely recognized by the market.

Its characteristics are mainly as follows:

High efficiency

Ultra-high operating efficiency, efficiency in the full working range of up to 0.75-0.85.

Strong self-priming

Super self-priming capacity and super high suction vacuum. The highest vacuum degree is 0.09MPa. That is, the self-priming height of 9 meters [is currently the world's strongest self-priming pump products, performance is no less than the vacuum system]].

High viscosity

Ultra-wide medium viscosity conveying range. It ensures that the medium from low viscosity to high viscosity can be easily transported, especially the places with high viscosity and high solid content can give full play to its special features. The maximum transportable viscosity value is 100000 mP · s, that is, 1 million cP viscosity materials.

High lift

The highest outlet pressure can reach 2.5Mpa, that is, the lift can reach 250 meters, which can meet the pressure required for pressure filtration of sewage such as biochemicals and wool.

Dry run

For the pump dry operation is not sensitive, so that its dry operation for 10 minutes will not cause damage to the pump.

No leakage

The sliding ring mechanical seal structure automatically compensates for wear, has a long life and ensures no leakage.

Long life

The self-designed special structure greatly extends the service life of the pump.

Reversible delivery

The structure is completely symmetrical arrangement: the pump inlet and outlet can be arbitrarily changed, and the reverse feed can be simply realized.

Fast maintenance

On-line maintenance, the pump end cover can be quickly disassembled, making maintenance extremely convenient without removing the pump from the system.

Multipurpose

Strong applicability, in the flow and pressure range, the use of special materials and special rotor form of the pump can meet the requirements of different working conditions.

High pass

Impurities through the ability to transport small particles, soft objects (such as fiber, wool), high viscosity and other impurities.

Lower overall cost

The cost of the pump is composed of three parts, namely, the purchase cost, the energy consumption cost and the maintenance cost. The purchase cost is only a small percentage of the total cost.

Related Products

We look forward to your message!

You can also submit your information online, and we will reply to you as soon as possible!