What are the advantages of Nord pump and gear pump

1. Ultra-wide viscosity range and impurity passing capacity have obvious advantages in places with high viscosity and high impurity content. There is no need to install a filter screen, and the flow and pressure are stable without fluctuation. 2. The sliding ring mechanical seal is used to automatically compensate for wear and the intermediate isolation cavity is designed, which is safe and reliable. Optional leak alarm device.

Jul 03,2024

Comparison of NORD pump and vacuum system

The suction vacuum degree is 0.09Mpa (9 meters), the self-suction ability is extremely strong, and the moving parts are designed with very little pollution by the conveying medium. The failure rate is extremely low, and the maintenance is simple, safe and stable. It only needs one pump to complete many tasks. There is no requirement for the matching of filters, frequency conversion, etc. The overall building block design is compact in structure, the equipment installation space is extremely small, and the maintenance is extremely simple, fast online repair without moving any equipment and professionals.

Jul 03,2024

What are the advantages of Nord pump and centrifugal pump

01. When conveying viscous or solid materials, it has high efficiency, can pass large-size materials, and has little shear on materials. 02. Optimize the three-blade spiral rotor, run smoothly without pulsation, and be more efficient and energy-saving. Compared to the centrifugal pump can save energy 15% 40%

Jul 03,2024

What are the advantages of Nord pump and screw pump

It can be operated dry, especially important in case of sudden material cutting and ring operation errors. It is extremely simple to avoid problems, with few over-current components, accounting for only 8% of the whole pump. It has low maintenance cost and small installation area, which is about 1/3 of that of single screw pump. It saves land cost and has a high pump rate. Compared with screw pump, it can be increased by 15%-30%. It can save energy and save online maintenance and clean online quickly, less maintenance time and intensity, saving maintenance costs.

Jul 03,2024

How to ensure that the blades of the rotary lobe pump do not interfere

Rotary lobe pump is a device that uses rotating cams and vanes to achieve liquid delivery. Among them, it is very important to ensure that there is no interference between the vane and the cam, because it is related to the performance and life of the pump. The following will describe in detail how to ensure that the blades of the rotary lobe pump do not interfere.

Jul 03,2024

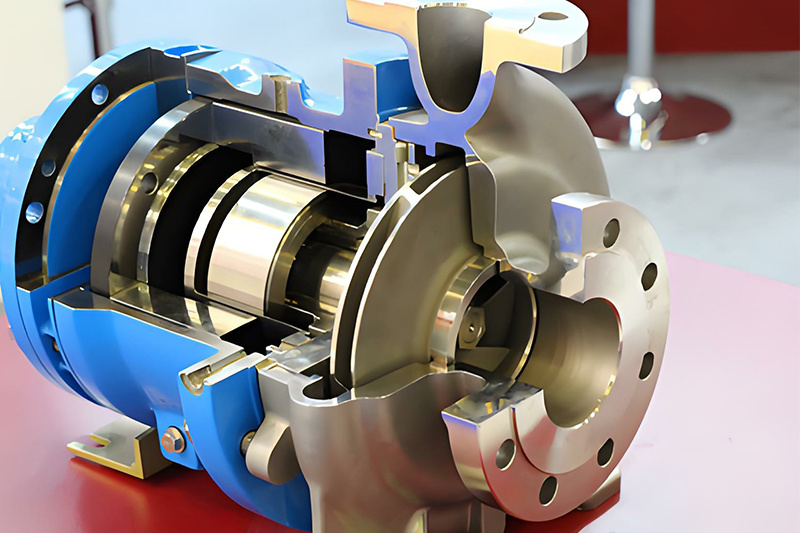

What is the working principle of the pipeline pump

Pipeline pumps, also known as centrifugal pumps or pipeline booster pumps, are widely used in various pipeline systems for liquid transportation and pressurization. Its working principle is based on the principle of centrifugal force and fluid dynamics, through the rotating impeller to pump and pressurize the liquid, so as to realize the circulation and transportation of the liquid. The following is a detailed explanation of the main working principle of the pipeline pump:

Jun 20,2024

What is the role of the pipeline pump

Pipeline pump, as a kind of fluid conveying equipment, plays an important role in modern industry, agriculture and daily life. Its main role can be summarized as follows:

Jun 20,2024

What is the difference between pipeline pump and sliding vane pump

Pipeline pumps and sliding vane pumps are commonly used in the industrial field of pump type, they have a wide range of applications in liquid transport. However, there are some significant differences in their structure, working principle, performance characteristics and so on.

Jun 20,2024

RELATED INFORMATION